Business leaders visit Cumbria Chamber Patron Leo Group in Penrith

On 25 April, we hosted the first Cumbria Chamber’s Power 40 event of this year at our Omega Proteins Site in Penrith.

Power 40 Group

Cumbria Chamber’s Power 40 group comprises business leaders from 40 of the county’s most influential businesses and it was truly a pleasure for us to offer our fellow Chamber members a look-behind-the-scenes of our Category 3 animal by-product rendering operation and to discuss the ongoing investments and improvements happening on-site.

Omega Proteins in Penrith

Our Omega Proteins is a Category 3 animal by-product processing plant and renders parts of animals that have been passed fit for human consumption in a slaughterhouse but have no market for consumption in the UK.

We process this material into oils and meals which are used in everyday products including SAF (sustainable aviation fuel), biofuels, pet food, aquaculture, oleochemicals and pharmaceuticals.

Sustainability and the environment

Following a presentation from Leo Group owner Danny Sawrij, joined by his son Leo Sawrij and other members of our team, the Power 40 group toured the site to have a close-up look at the whole rendering process as well as the various green technologies in place at the site.

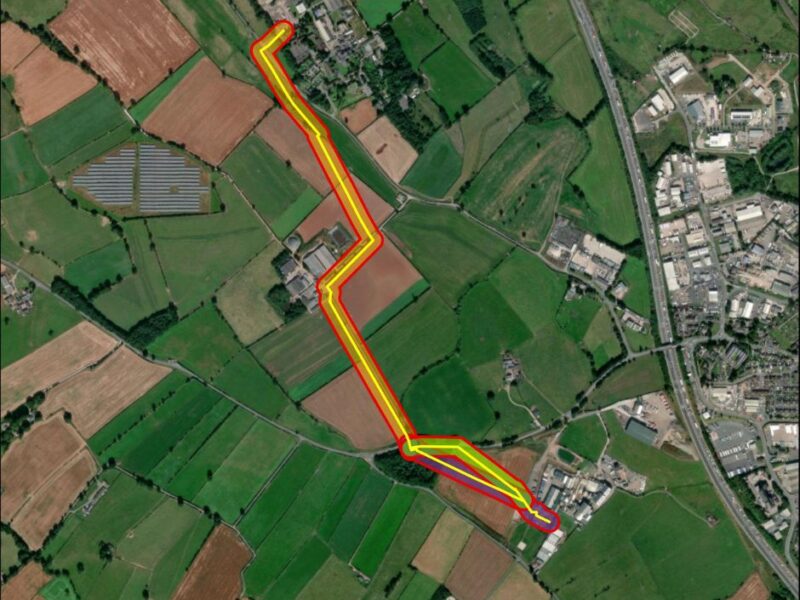

These included our water treatment plant and reed beds which recycle all of the facility’s wastewater and rainwater meaning that we are no longer rely on mains water. Our guests also saw the multi-fuel thermal oxidiser, which runs on biomass fuel to reduce CO2 in line with our company’s sustainability ethos. It also offers the potential to generate electricity from surplus steam using a simple steam turbine. The electricity can then be reused in the plant’s production processes, reducing the onsite electricity requirements.

We also explained that thermal oxidisers are one of three odour abatement techniques used at the site. They treat the air extracted from the process equipment at over 850 degrees to remove odours before it is released to atmosphere. A chemical scrubber and biofilters containing microorganisms are also employed. They are used to clean the less odorous room air.

The tour finished with a look around the new meal loading buildings which once completed, will allow finished product to be loaded onto trailers in an enclosed space. This will further reduce odour from the site and improve conditions for workers.

Feedback

It has been a fantastic day, and we would like to express our gratitude to the Chamber for organising this event. We also want to thank all attendees for their enthusiastic participation, engaging discussions over lunch, and the valuable feedback provided:

“I was part of a recent Cumbria Chamber of Commerce visit to Omega Proteins. We had a full access no holds bar visit around the site and processes, it was clear that Omega are leaders in their field and go above and beyond current legislation. The team we met were knowledgeable, professional and happy to answer all questions in detail. Cumbria is fortunate to have a world leader in their industry located here.”

“This was a really interesting morning that gave me lots to think about, many thanks for organising and to Leo Group Ltd and the inspirational Danny Sawrij for hosting us.”

“I agree it was an inspiring and informative visit. I know a lot more about Leo Group Ltd. Its leadership is constantly looking for improvement, very environmentally conscious, and the business is setting the standards in industry and sustainability. I took a lot away from the morning. Thanks Cumbria Chamber of Commerce and Danny Sawrij.”